DESIGN & ENGINEERING SERVICES

Our in-house CAD drawing services use the latest modeling and design software to deliver parts and tools to meet the precise specifications of our customers.

DESIGN & ENGINEERING SERVICES

We specialize in both tooling design and part manufacturability. Our in-house CAD drawing services use the latest modeling and design software to deliver parts and tools that meet even the most precise specifications.

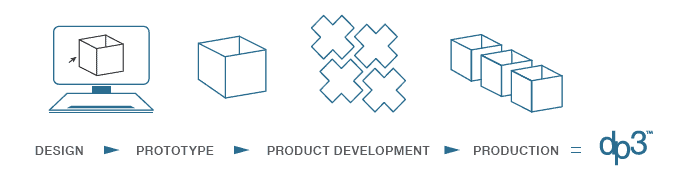

R&M offers design and engineering assistance to help our customers create the best parts and mechanical assemblies possible. We assist your engineering team with 3D modeling, rapid prototyping with 3D printers, prototyping using soft and hard tooling. R&M’s dp3™ process ensures that NPI parts are ready for pre- and post-production.

TOOLING DESIGN

R&M’s engineers are proficient in designing progressive dies for the life of your production parts. Whether 10 thousand or 10 million parts, we design tools that last for the entire product life cycle.

Our designers’ work with your CAD solid models to produce the die design using the latest version of Solidworks 3D CAD supported with the Logopress3 design module. We are able to use the solid design model with simulation to ensure that the design is correct and will run with no interference.

In addition to progressive designs, R&M also provides short run blanking, compound and forming tools.

PART MANUFACTURABILITY

We specialize in cost reduction by perfecting part manufacturability and exploring different ways to manufacture parts. This will help you stay within your project budget.

For example, we can completely stamp a part that was previously a subassembly. By implementing some minor changes, we can also stamp a part that was machined. We will work with your engineers to explore all production options.

R&M offers design and engineering assistance to help our customers create the best parts and mechanical assemblies possible. We assist your engineering team with 3D modeling, precision prototyping using soft and hard tooling.

R&M’s dp3™ process ensures that NPI parts are ready for pre- and post-production.